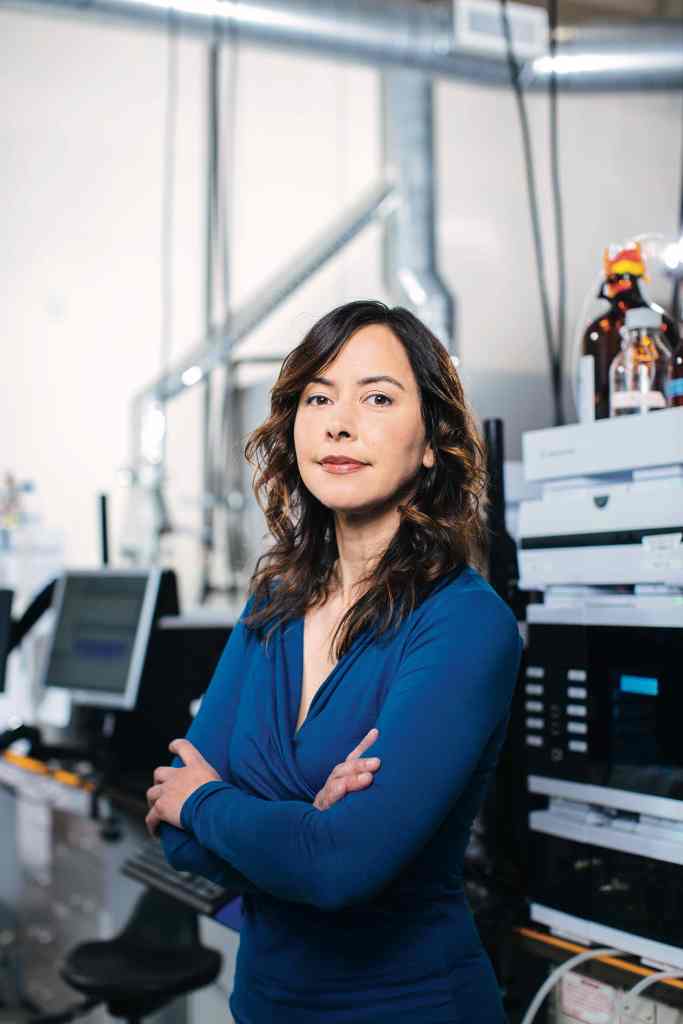

Backed by US$120 million in venture funding, Stanford professor Christina Smolke’s company Antheia just completed its first scaled production of a key drug ingredient.

Every year, thousands of people around the globe use a bioengineering process where they take sugar, feed it to a carefully selected strain of yeast and a few days later extract a product that’s then sold and enjoyed by millions. Most people call this brewing beer.

That’s basically all Christina Smolke’s company, Antheia, does. Instead of making beer, her company uses the same process to grow key ingredients for prescription drugs.

And instead of the yeast you might buy at your local homebrewing store, hers are the product of over a decade of research, bioengineered with genes from multiple species to produce specialty chemicals at scale and faster than conventional methods.

The company has announced it has completed its first commercial-scale fermentation run, which resulted in the production of 116,000 litres of thebaine, a key ingredient for several essential drugs.

Rather than a turnaround time of a few months, Antheia made the chemical in about five days. With this milestone in place, the company aims to go to market next year with its first products: key ingredients for drugs that currently face significant shortages.

According to an August survey from the American Society of Health System Pharmacists, shortages of essential medicines are forcing one-third of hospital pharmacists to ration, delay or cancel needed medical interventions.

The other two-thirds said they’re managing these shortages strategically but that there’s still an impact on patient care because the price of some essential medications have increased.

“Pharmacists have been managing drug shortages routinely for decades,” said ASHP CEO Paul Abramowitz. “But we’re now seeing longer, more persistent shortages.”

That’s the case with injectable opioids, which are used to manage pain for patients.

Traditionally, these ingredients are grown in fields for months or years, with crops being harvested and the needed chemical ingredients extracted so they can be compounded at a drug manufacturing facility.

However, relying on agriculture can cause problems, with issues arising from natural causes like pests or storms or industrial causes such as interruptions in shipping.

This is one type of drug ingredient that Antheia is focusing on – thebaine and oripavine, both of them key components in pain management and addiction management medications such as codeine, hydrocodone and naloxone.

The company has over 70 other ingredients in its pipeline for different types of drugs, including scopolamine, which is used in anti-nausea and anti-spasm medications.

“We’re producing ingredients where there are supply chains with recurring inefficiencies,” says Christina Smolke, cofounder and CEO of Antheia. “We’re looking long-term at where things are becoming unsustainable.”

While she was working on earning her PhD at UC Berkeley, Smolke, 48, says that she interned in the chemical industry, where she learned about traditional chemistry, like the science of refining oil.

That type of chemistry, she noted, scaled very well but wasn’t as versatile or flexible as the chemical reactions in biological systems–which don’t typically scale well. “I was beginning to think about the cell as a factory for making things,” she says.

This contrast inspired her to focus her research on developing microorganisms that can make useful products, first in a lab at CalTech and now at Stanford, where she is a professor.

“How can we take inspiration from nature but build more scalable production and biomanufacturing platforms?” she says. “Nature is our best chemist.”

In 2015, Smolke’s lab made headlines with a paper published in Science, which described how she and her fellow researchers could bioengineer yeast to produce hydrocodone, a common drug used to treat pain.

That same year, she cofounded Antheia along with biochemical engineer Kristy Hawkins and researchers Kate Thodey and Isis Trenchard, intending to scale up production to meet the needs of the pharmaceutical industry. (She also cofounded cancer immunotherapy company Chimera, where she still serves as a scientific advisor.)

Antheia’s researchers first had to engineer the yeast to make large quantities of drug ingredients.

That process involved taking genes from the plants from which the drug ingredients are harvested and adding them to the yeast, along with genes from over 20 other organisms, to make the process more efficient.

ATHEIA

This is much more complicated for the yeast than turning sugar into alcohol for beer, which only involves two chemical steps. Making drug ingredients involves at least two dozen more and a bunch of custom enzymes.

While this is relatively easy to manage in small batches at the lab, where the conditions are easier to control, doing it at an industrial scale requires a lot of complex engineering of the equipment, temperatures and fermentation conditions.

To develop the techniques they’d need to scale commercially, Antheia partnered with an undisclosed Italian biomanufacturer in 2021.

Antheia is the only synthetic biology company focused on the niche of making drug ingredients, according to Kazi Helal, a biotech analyst for Pitchbook. That could give it an advantage, but he also noted, “There might be a good reason why there’s not that many competitors in the space.”

Amyris, using synthetic biology to develop ingredients for beauty products, announced a Chapter 11 bankruptcy earlier this month and says it will be exiting the consumer market.

That said, Helal notes that by focusing on pharmaceutical companies delivering essential medicines, “there’s a viable path to commercial success” if the company can deliver at scale.

Smolke acknowledges that scale is a major challenge for the start-up to offer a real supply chain alternative but points to her company’s announcement of a commercial-scale batch of thebaine as “an important proof point because it demonstrates the technology is real, it can now scale, and it can meet the commercial metrics.”

The market challenges certainly haven’t deterred investors. The company has raised US$120 million from investors such as Viking Global, Sherpalo Ventures, and billionaire Eric Schmidt’s investment firm Hillspire.

Pitchbook estimates the company’s valuation at US$270 million (Antheia disputes this number but declined to provide a correct figure).

Additionally, in 2021, the company partnered with synthetic biology company Ginkgo Bioworks, which is developing custom enzymes for Antheia’s fermentation process.

The next step for Antheia and its 52 employees is to get the company ready to put its products on the market at full scale, which will require regulatory approval from the FDA and other agencies.

That means proving that the drug ingredients produced by its bioengineered yeast are the same quality as those produced conventionally. Smolke says that if all goes well, she expects to receive FDA approval by the end of the year, with the company officially going to market in 2024.

“This is going to set up a transformation within the industry to move to a more efficient, agile and cost-effective way of production,” she says.

Forbes Australia Issue 7 is out now. Tap here to secure your copy.