‘Red dress, beach wedding?’ This AI will measure you, design it and deliver it without you leaving home.

Key Takeaways

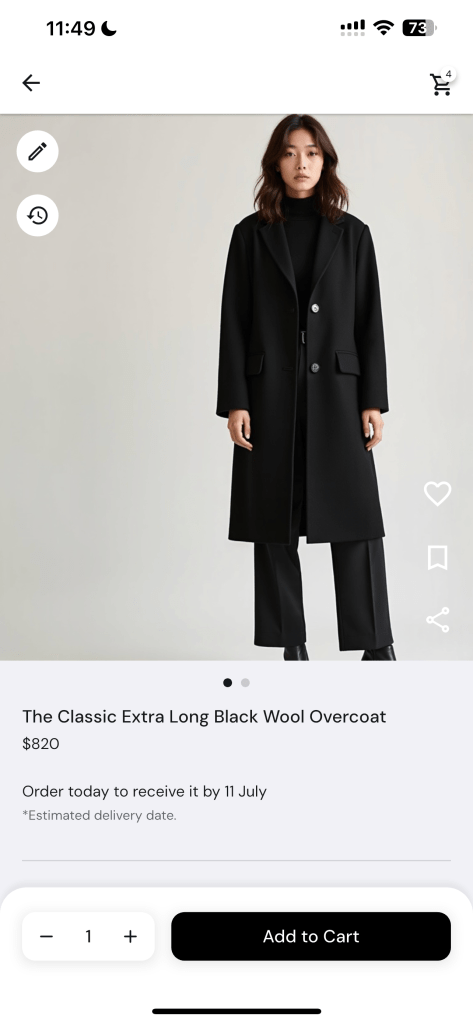

- THDR Group’s Neuono fashion label promises to create made-to-measure garments for anyone around the world without the need for in-person fittings or store visits.

- Powered by AI models from OpenAI and Google alongside proprietary models, Neuono was developed by Australian start-up THDR Group, which launched in 2021 selling men’s suits.

- Neuono blends 3D body mapping from the customer’s phone, with styling algorithms that keep their digital fingers on the fashion pulse to generate garments from formalwear to jeans.

- Neuono has partnered with five Chinese factories to make individual AI-generated garments with a potential for 16 quadrillion construction combinations.

Key background

THDR Group’s label Neuono claims to be the world’s first AI fashion brand, launching today, not at London Fashion Week, but London Tech Week – claiming16 quadrillion possible design combinations.

“The thesis of the company is that the future of fashion is made-to-measure instead of ready-to-wear,” THDR Group co-founder Sean Fagan tells Forbes Australia.

Claims to the title of “world’s first AI fashion” this or that are not new. Korean designer YounHee Park claimed it in 2022 with a runway collection. An AI Fashion Week was launched in 2023.

The difference, says Fagan, is that while AI has been able to design clothes, create mood boards and even predict fashion trends for some time, it can’t take it through to manufacture.

“We take all the inputs from the user prompt, as well as information about the user’s tastes, their hair colour, their age. And the AI is able to develop unique products specifically for that user, all of which we can manufacture,” says Fagan.

“There’s a whole tech pack, for lack of a better term, in the background. You say ‘I want a red dress for a beach wedding.’ Other platforms can design you the dress, but they can’t have it delivered to your door in under four weeks.

“We select real-world fabric. We’ve made sure that our supply chain can actually do what the design says: that the pocket in the picture, the lapel, the hemline can all be actually achieved.”

“How it will get there is through automated factories onshore and near shore. That’s a five-year timeline like a Series A or Series B sort of problem that we want to solve.”

Sean Fagan, THDR Group co-founder

Fagan and co-founder Timothy Aquino recently returned from their fifth visit to China in 12 months, spending two weeks there talking to their five manufacturing partners, wtith each equipped to handle different types of garment, from jeans to summer frocks to men’s suits.

‘Scrappy but efficient’

Fagan and Aquino started THDR in 2021, focusing on men’s suits and spending the first six months developing a reliable way to measure customers’ bodies using just a smartphone.

Since then, their Theodore app has been downloaded over 30,000 times, with 20,000 users completing full-body scans — enough to train their AI measurement system to what they claim is a 97.5% accuracy rate. That data now powers Neuono’s personalised fitting engine.

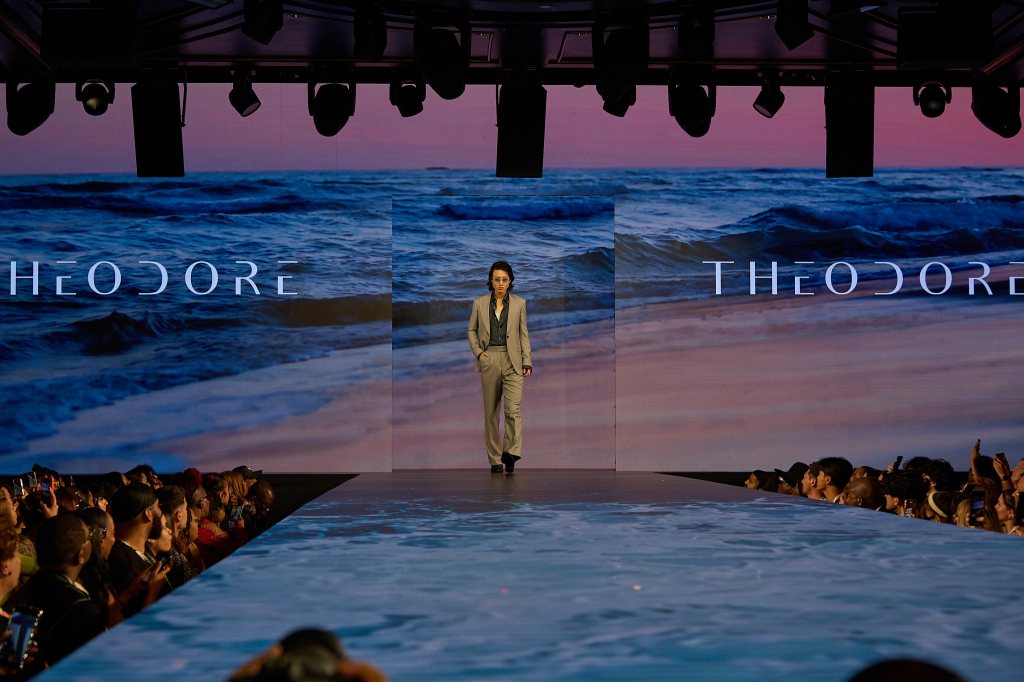

They’ve also proved they can build a brand. Theodore was nominated for the National Designer Award and recently held a runway show at New York Fashion Week.

The company’s chief product officer, Olivia Yuqi-Zhai, helped build the design model from the ground up. Her background spans data analytics and fashion — crucial for wrangling the staggering number of potential fabric, linings, button and silhouette combinations.

The AI model can currently generate 16 quadrillion unique construction variations when taking into account all the different fabrics and design nuances, says Fagan.

Neuono has been almost entirely bootstrapped. Fagan coded the app and backend systems himself. “It’s made us scrappy,” he says. “But efficient.”

He and Aquino still own close to 100% of the business, aside from a small convertible note and an employee share option plan. “Theodore has funded it,” says Fagan. “And now it’s time for Neuono to take the next step.”

How it works

The process begins when the user uploads a selfie and takes a front and side picture wearing as little as possible, or tight-fitting clothes. These images are used to analyse facial features (like skin tone, eye and hair colour) as well as body shape and proportions.

From there, users input a simple style prompt — for example, “boardroom outfit for 60-year-old man,” or “garden party with young royals”.

Neuono’s proprietary AI model, called SenseThread, gets to work, generating designs tailored to the prompt and the user’s physical traits, style preferences.

The system also performs real-time trend research to understand current fashions.

Each generated garment includes both front and back views, a product description, garment specifications (fit, fabric, sleeve length, care guide, etc.), and a rationale. This reasoning is drawn from a secondary AI model trained to explain choices — why a particular neckline works for a user’s frame, or why certain colours complement their complexion.

Rather than offer virtual try-ons with their own image wearing the clothes (which users often find off-putting), Neuono displays an idealised model who shares the user’s features — from hair colour to body shape.

The platform also adapts over time: if a user repeatedly dislikes garments with, say, orange stripes, those will be filtered out in future sessions. Buying a garment becomes the strongest indicator of taste, helping refine the user’s “style fingerprint”.

Once a garment is chosen, there’s no need to select a size — Neuono’s AI has already done that, based on body scan data. Each piece also includes an embedded NFC chip for future integrations or potential smart features.

Five-day fashion inflection

The theory is that if they can turn around a garment in five days from design to delivery, then fast fashion will crumble under made-to-measure’s superiority, says Fagan.

“At the moment, the Neuono brand is promising a four-week turnaround. It’ll potentially be shorter, but we just want to ensure we’re managing expectations.” To get to five days, manufacturing needs to be closer to the major markets.

“How it will get there is through automated factories onshore and near shore. That’s a five-year timeline like a Series A or Series B sort of problem that we want to solve. It’s very capital intensive.”

“There’s a lot of things we have to solve. We’re focused on this first step of going, okay, AI can design. Consumers want this. We prove that out. Then the next step is, okay, how do we make this faster? How do we make it more efficient, more convenient for the user? And so keep cropping that market share.”

The counter couture argument

Prominent fashion designer Jonathan Ward who now focusses on couture having worked across the spectrum of corporates from Yves Saint Laurent to RM Williams to Qantas, says the Neuono technology “sounds pretty amazing”, but he has reservations.

“The body is pretty fluid. Something can be incredibly fitted and firm one day but there’s no guarantee it’s going to fit the next. Particularly for women. Their scanning system would have to be able to take into account that it’s very common for a woman to have one hip higher than the other or one bust bigger than the other, or a lower shoulder.

“But the idea of this for larger people, or taller people is fantastic. People that have got difficult sizing to be able to have this service, would be fantastic.”

Ward doubted such a system could impact the world of couture.

“It’s one thing to cut and sew a lace dress and just have seams. It’s another thing to overlay it by hand with a whole lot of extra work that covers seams and things like that, so everything gets to a certain stage and then it becomes another elevation.

“If it’s tailored or semi-tailored, I don’t see why they can’t do it though.”

And he never buys fabric online. “The colour’s never the same and the feel of it and the drape of it, or the structure of it, it looks very different.”