Sydney-based Crest Robotics and Earthbuilt Technology have unveiled “Charlotte,” a world-first building robot designed to tackle Australia’s housing crisis and construct sustainable shelters on the lunar surface.

Key Takeaways

- “Charlotte” is engineered to operate on the Earth and the Moon, advancing low-cost housing and future space exploration.

- It will be showcased at the 76th International Astronautical Congress 2025 being held in Sydney next week.

- It is capable of assembling a 200m² home in one day with low carbon emissions.

- Uses local raw materials – including earth, sand and waste – to eliminate costly supply chains.

- Addresses Australia’s housing shortage and construction productivity slump, claiming it can build up to 5,000 times faster than conventional methods.

- The project is supported by SmartSat CRC and funded by the NSW Government’s NSW Space+ program.

Key background

Crest Robotics, founded to boost safety and productivity for blue-collar workers, has teamed with another Sydney-based firm, Earthbuilt Technology, to tackle two pressing frontiers: Australia’s housing affordability crisis and humanity’s push into space.

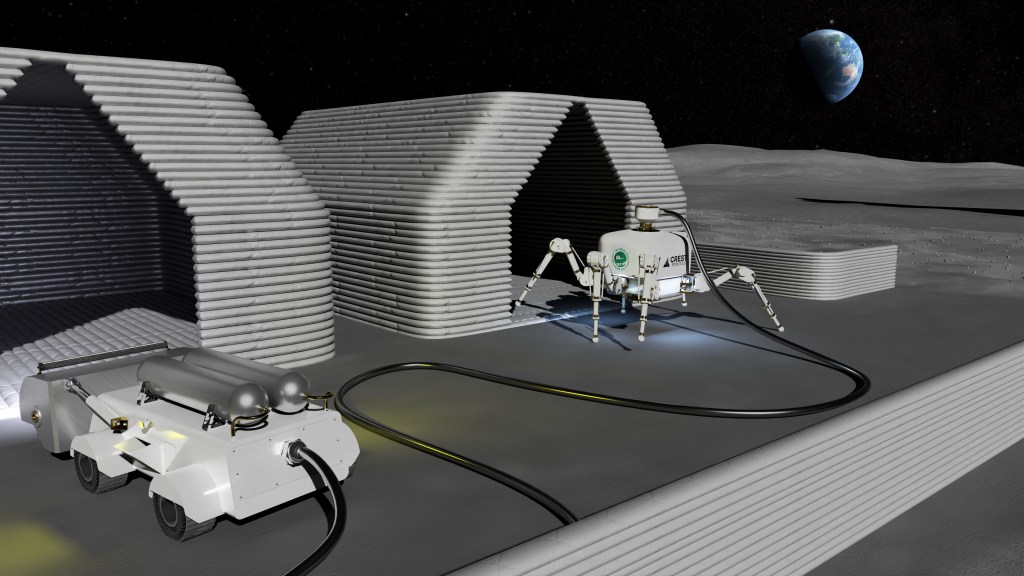

Their robot “Charlotte,” to be unveiled at the International Astronautical Congress in Sydney, combines Crest’s robotics expertise with Earthbuilt’s extrusion and compaction technology. The system can autonomously transform raw local materials into dwellings, bypassing the traditional, carbon-heavy supply chain.

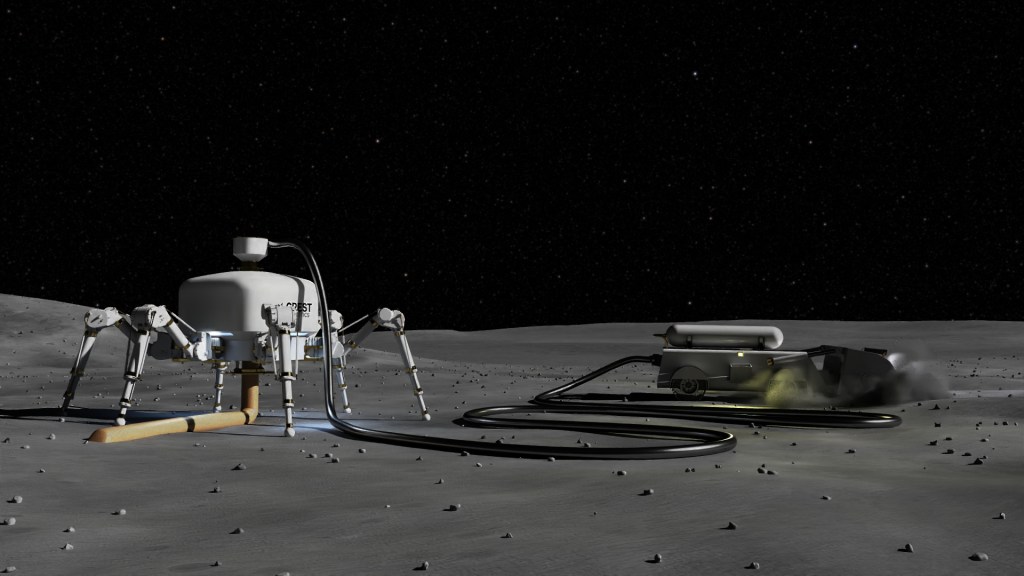

For the Moon, Charlotte’s lightweight, autonomous, spider-like design is seen as better suited than hydraulic machinery, which is too heavy and maintenance-intensive for lunar conditions.

“Charlotte” works by collecting raw materials such as sand, earth and even waste materials like crushed brick or glass, then binding them in fabric and compressing it all to form the layers of a building, Jan Golembiewski, founder and CEO of Earthbuilt Technology explained.

“Every step of building a home requires human input, which adds costs and carbon,” Golembiewski said. “With supply-chains longer and more complex than ever, materials have become increasingly expensive, carbon-intensive and wasteful. Earthbuilt reverses this.

“Making a simple brick, for example, requires around 50 different processes and inputs. By contrast, Earthbuilt’s technology uses only three: earth, fibre and energy. When integrated with advanced robotics, Charlotte’s efficient and lightweight design minimises energy expenditure,” explained Golembiewski.

Tangent

Australia’s construction industry has been battling historic inefficiencies. According to the Committee for Economic Development of Australia (CEDA), productivity has halved since the 1970s, with the number of dwellings completed per worker sharply declining. Meanwhile, demand for housing continues to surge, pushing governments and industry to consider unconventional approaches.

Charlotte’s Earth–Moon dual capability places Australia at the intersection of solving domestic housing challenges and advancing its role in global space exploration.

Big Number

1,500–5,000

That’s how many times faster Charlotte’s construction method is compared to traditional building processes, according to its developers.