Landfills are overflowing with plastic trash. Serial inventor Jonathan Rothberg’s Protein Evolution found a solution: using AI to create enzymes that can recycle old polyester textiles into a material that acts new. Now the three-year-old company needs to prove that it can scale up.

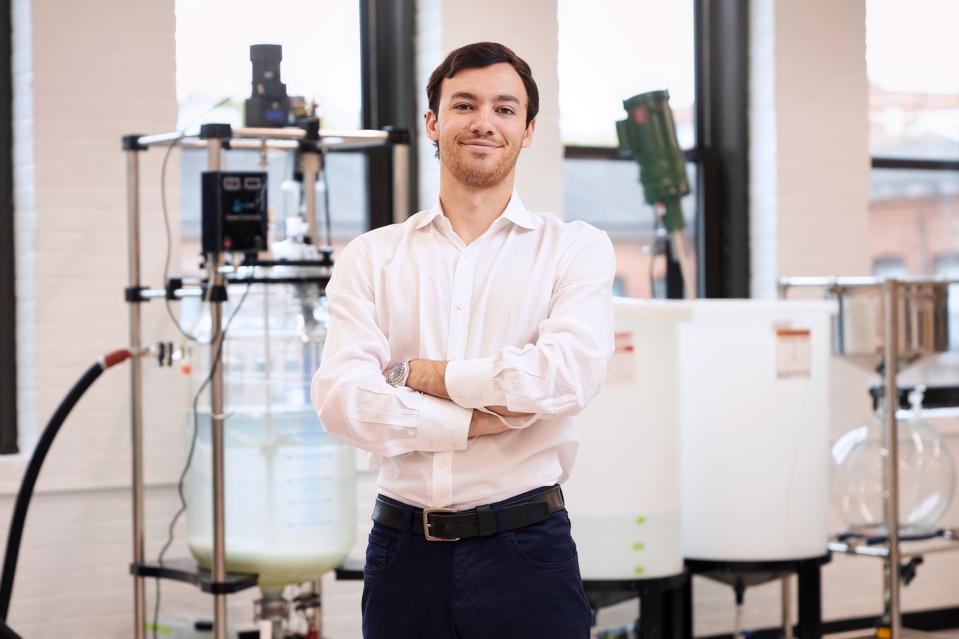

Protein Evolution cofounder Connor Lynn: “We’re excited about textile waste because the mechanical recycling technologies are unfit to process it.”

SHIRLEY YU/PROTEIN EVOLUTION

In a lab tucked away in an old gun factory in New Haven, Connecticut, a machine heated plastic waste to 536 degrees Fahrenheit and spat out gloopy strings of material that start to harden when they hit the air. This substance — made of textiles and post-industrial scrap that were destined for a landfill — will be ground to bits to create as much surface area as possible.

It’s about to become food for an enzyme designed with the help of artificial intelligence, made by the startup Protein Evolution. The company’s ambition is to use AI to engineer new enzymes that are able to break down plastics and plastic-based textiles.

“What happens next is we feed it to the sharks,” joked chief technology officer Jay Konieczka, who stood with a white lab coat next to a reactor filled with enzymes and water, which will break the plastics down to their core components. The resulting material, from the process the company calls Biopure, is supposed to be indistinguishable from polyester made from petroleum, and can be used the same way in fabrics. Protein Evolution hopes its enzyme process will allow old clothes, sheets and other textiles to become fully recyclable.

The world has a serious plastics problem, with some 460 million tons total produced annually, a number that will only rise as we buy more stuff. Only 9% of plastic is actually recycled, according to the Organization for Economic Co-operation and Development. The rest ends up in landfills or incinerated — and that’s what Protein Evolution cofounder Jonathan Rothberg said he wants to target. “You have to recycle the 91% that people don’t recycle: All this crap, all this mixed stuff, not the perfectly clean water bottles that have been rinsed,” said Rothberg, a serial inventor and entrepreneur who’s best known for inventing and commercializing high-speed DNA sequencing.

This 91% is where scientists see potential for what’s known as biological recycling: using enzymes that break down plastic quickly without creating microplastics or degrading the material in the process. But the number of possible plastic-eating enzymes is greater than the atoms in the known universe, which has made it difficult for researchers to make much headway.

Enter artificial intelligence. “In the last five years, the world of enzyme engineering has blown open because of AI,” Konieczka said. Protein Evolution’s proprietary AI model incorporates publicly available data on tens of thousands of proteins that help it spew out thousands of amino acid sequences that represent new enzymes. Protein Evolution then uses algorithms, including the AlphaFold AI system developed by Google DeepMind that predicts a protein’s structure from its amino acid sequence, and tests the ones that look most promising in the lab’s reactors.

When Protein Evolution started, most of the new enzymes the AI model suggested were “garbage,” Konieczka said, but as the team incorporated new information about what was working and what wasn’t, over time the AI model learned to design better plastic-devouring enzymes.

Konieczka figures that he can continue to tweak the design so they’ll work faster or at slightly lower temperatures — making the entire process more efficient and cheaper. “We’ve been focused on cost from day one,” said Connor Lynn, Protein Evolution’s cofounder, who runs the business.

Armed with $25 million in venture funding and plans to raise at least that much more this year, the three-year-old startup is gearing up to build a pilot plant that could produce 300 tons a year of recycled plastic in 2025. After that, it hopes to build a commercial plant, with capacity of 50,000 tons a year, in 2028.

“You have to recycle the 91% that people don’t recycle: All this crap, all this mixed stuff, not the perfectly clean water bottles that have been rinsed.”

Jonathan Rothberg, Protein Evolution cofounder

Protein Evolution isn’t the only company trying to make biological recycling a reality. French company Carbios, which is publicly traded with a market cap around $400 million, broke ground last week on a PET biorecycling plant near the Belgian border with 50,000 tons of capacity. And Breaking, which relies on a microbe known as X-32 that chews and eats plastic, recently spun out of Colossal Biosciences, the startup cofounded by Harvard geneticist George Church and entrepreneur Ben Lamm that’s best known for trying to resurrect the woolly mammoth. “We think this is an existential problem where there should be 1,000 companies working on this,” Lamm said.

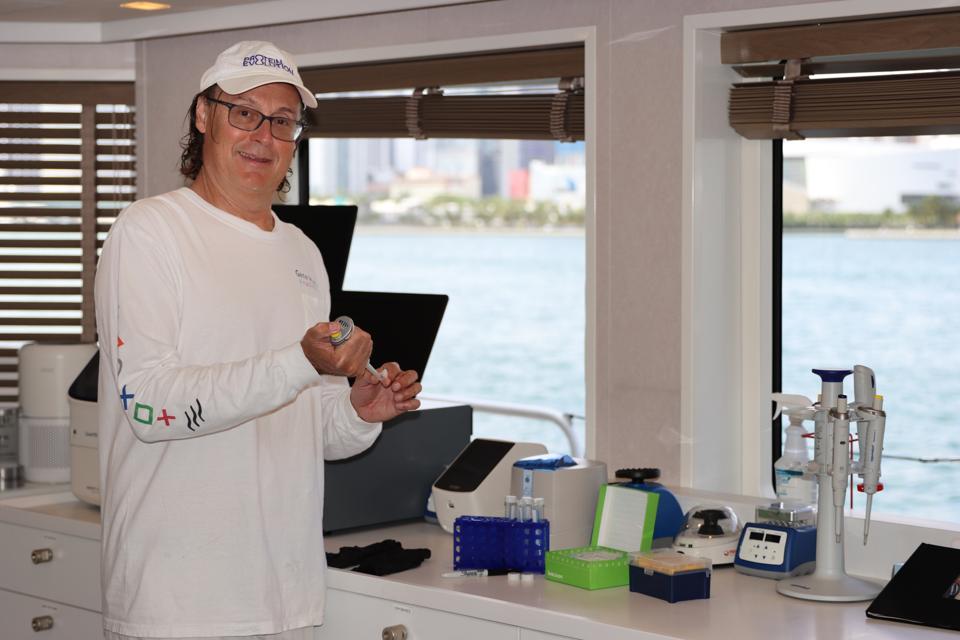

Protein Evolution cofounder Jonathan Rothberg aboard his research yacht, his base for testing new ideas and starting companies.

Protein Evolution

For all these companies, it’s early days still, and scaling up comes with risk. Today, Protein Evolution brings in only a small amount of revenue from development deals with a handful of consumer brands, including British designer Stella McCartney. To get to commercial scale, Protein Evolution will need to build out its 50,000 ton plant, insert itself into the plastic waste disposal supply chain to get or buy enough material to recycle, and keep its costs low enough that brands will be willing to buy its polyester.

“There would be no reason the technology can’t work and can’t scale. We use enzymatic technology in all kinds of other industrial processes,” said Richard Wielechowski, a senior investment analyst in textiles at Planet Tracker. Enzymes are used in wastewater treatment and drug manufacturing, for example. “The real caveat for me is always cost.”

Lynn expects annual revenue from the coming pilot plant to reach single-digit millions next year, and for the first commercial facility to hit $100 million in revenue soon after opening. “You can’t solve the climate problem without solving the plastics problem,” he said.

Jonathan Rothberg, 61, spends his days on a 182-foot yacht anchored off the coast of Miami that’s outfitted as a complete lab with PCR machines, 3D printers and other equipment. Rothberg, who received the National Medal of Technology and Innovation for his work on DNA sequencing, has founded a dozen companies, including one that designed at-home PCR tests for Covid-19 during the pandemic’s early days (Detect) and another that shrank down ultrasound machines to handheld size (Butterfly Network).

After selling a previous enzyme-related company called RainDance Technologies to medical diagnostics firm Bio-Rad Laboratories for $73 million, he and 25-year-old Lynn, who had been working with him on strategy and finance at his other startups, started researching what else they could do with enzymes. “We had been incubating the enzymes, but we didn’t have the killer app,” Lynn said.

Evidence that enzymes can degrade plastics goes back decades. In 2016, a Japanese research team published a paper showing an enzyme called “PETase” could chew through PET bottles. But nature didn’t design the enzyme to work on plastic; it would need to eat through plastic much faster to make a dent in the plastic waste problem. But if the right enzyme could be developed, it would be ideal for dealing with plastics, which can take hundreds of years to decompose in a landfill and even then just turn into smaller and smaller microplastics.

Rothberg realized plastics could be an ideal focus for developing new enzymes with AI after he was introduced to Ludwik Leibler, a physicist at ESPCI ParisTech who had been studying the performance of plastics for decades. The ESPCI team had been working on engineering enzymes that could break down polymers into their building blocks known as monomers to allow recycling.

“Ludwik said, ‘Look, it’s not just about eating up plastics,’” Rothberg said. “Plastics aren’t even ready to be eaten up, they’re not in a configuration that allows the enzymes to get close enough so no matter how you engineered the enzymes you would never get that Pacman first bite. First, you have to open up your plastics and then you can apply your enzyme technology.”

In October 2021, Rothberg and Lynn launched Protein Evolution to focus on plastics recycling. (The firm, like Rothberg’s other early-stage startups, does not yet have a CEO.) Then the group’s researchers started designing enzymes using AI to sort through the unimaginable number of potential enzymes at speed.

“The combination of using AI and biological engineering has enabled them to move very quickly,” said Sophie Bakalar, an investor at Collaborative Fund, which studied numerous plastics recycling outfits before investing in Protein Evolution. “AI is such a hot topic right now, but they truly have been working on using this from the beginning. They are not a company jumping on the hype train.”

Weaving fabric from polyester yarn made with Protein Evolution’s recycled material

Protein Evolution

To show off its biological recycling process, Protein Evolution teamed up with fashion designer Stella McCartney, sending her recycled materials made from some of the gnarliest plastic waste they could find: the heavyweight industrial straps used to secure freight containers. At COP 28, the United Nations climate change conference in Dubai last December, McCartney showed off a billowy, oat-colored jacket she’d produced with the materials, the first garment ever made using biological recycling.

While the jacket was just for show, McCartney, a long-time proponent of sustainable fashion, told Forbes she hopes to use the company’s materials in her ready-to-wear clothes and vegan accessories. “Solutions like Protein Evolution are the future of fashion – one where we can transform waste through circularity and recycling, creating desirable luxury-quality products without using any new materials,” McCartney said by email.

As a special advisor on sustainability to fashion giant LVMH, McCartney also said she was promoting the materials to LVMH and its billionaire chairman and CEO Bernard Aurnault. “I hope they will continue to follow our sustainable lead,” she wrote.

Protein Evolution has signed development agreements with five fashion brands so far in addition to Stella McCartney, Lynn said, though he declined to name them citing non-disclosure agreements. It now has an aggressive timetable for commercialization. Lynn hopes to get government incentives to build the new facility, and also thinks that state regulations, such as Massachusetts’ ban on sending textiles to landfills, will provide a push by increasing demand for recycled plastics. He also said that the company should be able to produce its recycled polyester at a price that’s just about equivalent to petroleum-based new material.

“Nothing takes off till it’s the same price as the thing you are replacing,” Rothberg said. “The processes they are developing now are competitive with virgin plastics, and it becomes more competitive if we have war all over the place and oil goes up. I think when oil is over $80 a barrel [as it is today], we’re not just equal—we’re better.”

Tiffany Hua, an analyst at Lux Research who follows textiles and textile recycling, said that there’s huge promise from enzymatic recycling, but that it’s still an early-stage innovation and the big questions for Protein Evolution will come as it builds out its plants. “I would consider it a moonshot innovation,” she said. “There’s a lot of tweaking with industrial processes and it’s even more complex with these biological recycling processes.”

The first garment made using biological recycling: Stella McCartney’s jacket made with Protein Evolution’s materials, which debuted at COP 28.

Protein Evolution

Longer term, Lynn hopes to gain traction beyond fashion, and to work on recycling synthetic materials beyond polyester, such as nylon or perhaps even fabrics that have been coated with ‘forever chemicals,’ or PFAS. “Polyester is everywhere,” he said. “Getting into low-cost apparel and alternative uses for polyester and rugs is of interest to us, as is moving into packaging.”

A potentially bigger goal that Protein Evolution is considering: use enzymes to develop a new type of plastics altogether that biodegrade on their own. That’s been a holy grail for those who care about the environment.

“Once you break PET down into its fundamental building blocks, can you put it back together as PET? Yes, absolutely. Can you put it together in different things with new properties and applications? Yes, you sure can,” said Paul Anastas, a Yale professor of chemistry for the environment and former top EPA official who serves as a science advisor to the company. “This is not just about taking apart the pieces and putting them back together in an identical way. This is about turning bad plastics potentially into good plastics.”