Backed by fresh capital, Australian start-up Uluu is set to scale its seaweed-based plastic alternative, aiming to disrupt the US$700 billion global plastics industry.

Perth-based biomaterials start-up Uluu has secured $16 million in Series A funding to scale its seaweed-based alternative to plastic, with its co-founders and co-CEOs saying the fresh capital marks a major step toward industrial production and commercialisation.

The round was led by Burda Principal Investments, the growth arm of Germany’s Hubert Burda Media, with support from Main Sequence, Novel Investments (the family office of one of the world’s largest textile groups), Startmate, and a group of family and impact investors including Fairground and Trinity Ventures. The cash injection will fund construction of a 10-tonne-per-year demonstration plant in Western Australia, a one-hundredfold scale-up from Uluu’s existing 100-kilogram pilot facility.

“Uluu is at a really exciting place,” says co-founder and co-CEO Dr Julia Reisser. “We’ve been running our test plant for two years and are now ready to scale up. The $16 million enables us to increase production one hundred times from our current 100 kilograms per year, deliver significant volumes to customers, and give brands the confidence needed to enter multi-year offtake agreements ahead of our first commercial plant in 2028.”

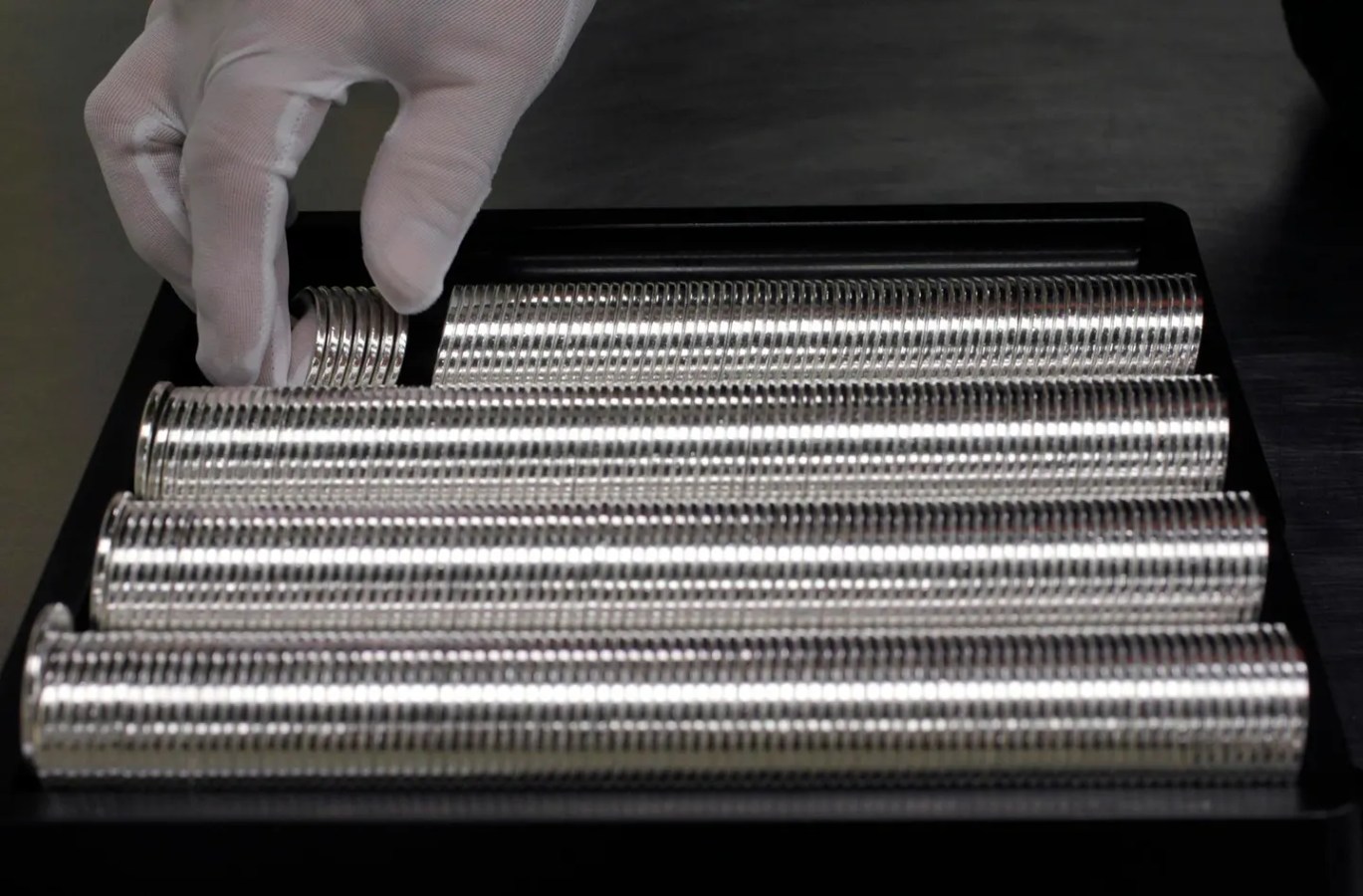

Founded by Reisser, a marine scientist, and co-CEO Michael Kingsbury, Uluu converts farmed seaweed into a natural polymer that looks, feels and performs like conventional plastic but breaks down naturally without releasing microplastics. The company’s process combines seaweed with fermentation to create natural polymers called PHAs that eliminate dependence on fossil fuels and persistent plastic pollution. At scale, it is also climate-positive: for every kilogram of Uluu produced, around 5 kilograms of CO2-equivalent are sequestered or avoided, compared with roughly 3 kilograms emitted in the production of conventional plastic.

The decision to raise capital now was driven by Uluu’s readiness to move from research and development to scaled production. “We chose to raise capital now to build a 10-tonne per year demonstration plant in Western Australia, which is a critical step in showing Uluu can scale to truly compete with and replace fossil plastics,” she says.

Related

Over the next 12 to 18 months, the company’s focus will be on completing construction of the new facility and supplying customers with commercial-grade material for the first time. That increase in volume will allow partner brands (like Quiksilver, Papinelle and Audi) to move from prototyping into staged trials, paving the way for the long-term offtake agreements needed to underpin Uluu’s first commercial plant. That commercial plant is expected to be operational in 2028, initially producing around 3,000 tonnes a year before ramping up to 10,000 tonnes by 2030.

Reisser says Uluu’s lead investor, Burda Principal Investments, has a track record of backing high-growth sustainability and technology ventures globally, and their understanding of industrial innovation and presence in South East Asian markets (close to seaweed farming and manufacturing hubs) made it an ideal partner.

“They understand both our pioneering technology and our mission to redefine how materials can be produced more sustainably at industrial scale.”

Main Sequence (the CSIRO-linked deep-tech fund), which led Uluu’s earlier seed funding, also participated in the round. Uluu’s seed round actually drew attention back in 2022 for its celebrity investors, including supermodel Karlie Kloss and Tame Impala frontman Kevin Parker, who invested through Voice Capital.

According to Statista, the global plastics market was valued at about US$700 billion in 2023, and is expected to experience considerable growth over the next decade. The company’s so far had success with companies in cosmetics packaging, fashion accessories and textiles and automotive interiors, but the next frontier will be about refining its process to reach cost parity with fossil plastics.

“Seaweed grows quickly and gets everything it needs from the sun and the sea,” Reisser says. “It locks away CO2 and helps clean up pollutants from the ocean. “By harnessing seaweed, Uluu is producing materials that have a positive, rather than negative, impact on the environment, while ending plastic pollution.”

Look back on the week that was with hand-picked articles from Australia and around the world. Sign up to the Forbes Australia newsletter here or become a member here.